Extrusion format

This page contains information about the new Extrusion Format.

- dimensions

- part list

- power supply spec.

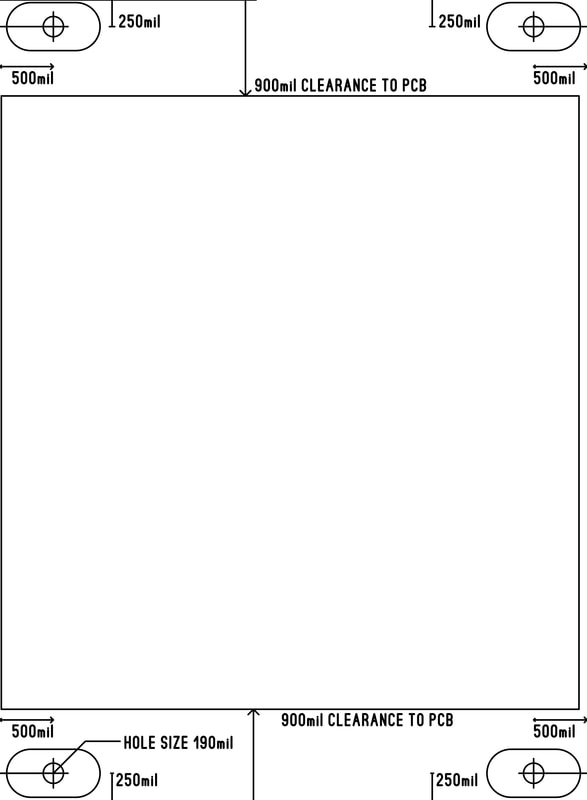

Dimensions.

Here is an example of EXTF-7.5, 5.5" wide module.

Here is an example of EXTF-7.5, 5.5" wide module.

| extf-7.5_dimensions-width5.5.pdf | |

| File Size: | 8 kb |

| File Type: | |

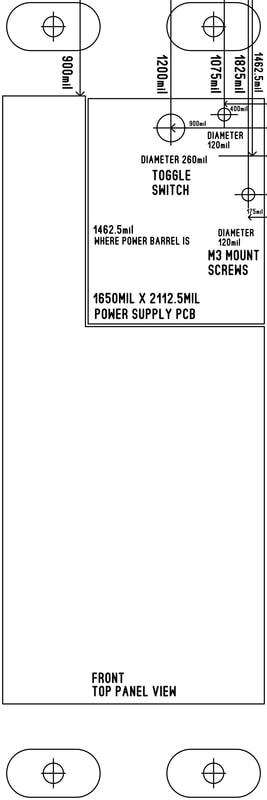

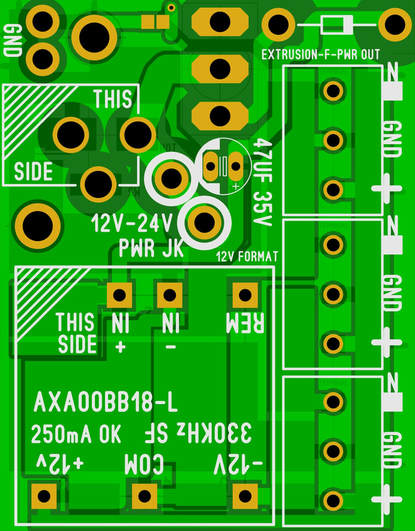

Here is an example of a power supply.

The power barrel is 1.462" down from the front panel top portion.

The power barrel is 1.462" down from the front panel top portion.

| extf-7.5_power_supply_example.pdf | |

| File Size: | 11 kb |

| File Type: | |

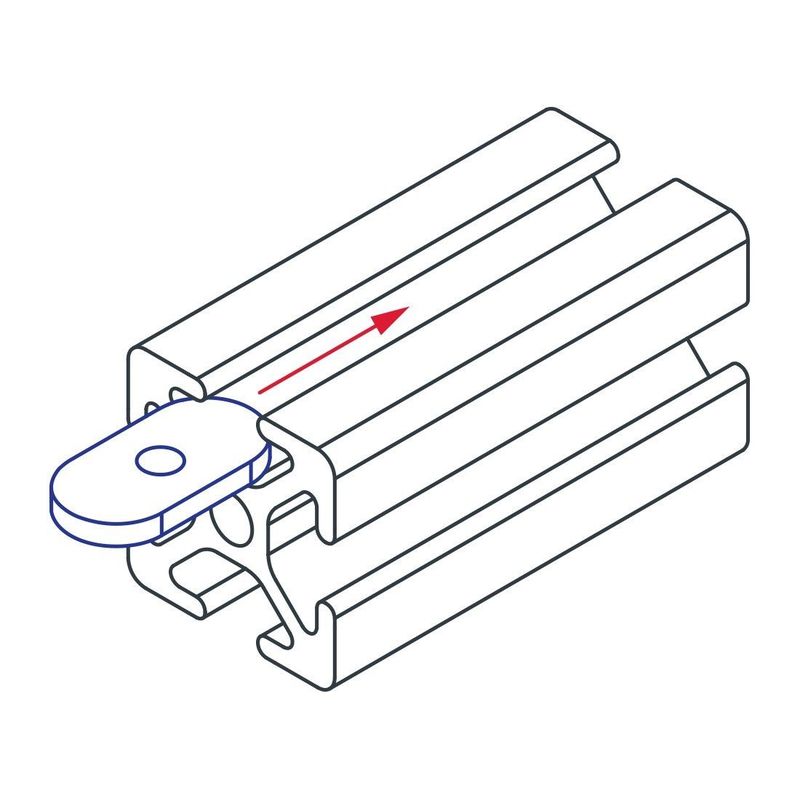

Part list.

*80/20 Inc T-Slot 10 Series 10-32 Slide-In Economy T-Nut #3276

*FEET SCREW: 10-32 X 1/2" PHILLIPS PAN

RUBBER FEET + PCB + SLIDE NUT.

*MOUNTING SCREW: 10-32 X 3/8" PHILLIPS PAN

PCB + SLIDE NUT.

1X1 EXTRUSION (LEVEL 1 PCB)-DESKTOP

2X1 EXTRUSION (LEVEL 2 PCB SANDWICH)

*M6 TAPPING TOOL REQUIRED FOR EXTRUSION PREPARATION.

*M6 SCREWS: M6X12mm FOR SHEET SIDES, M6X20mm FOR THICKER SIDES.

*80/20 Inc T-Slot 10 Series 10-32 Slide-In Economy T-Nut #3276

*FEET SCREW: 10-32 X 1/2" PHILLIPS PAN

RUBBER FEET + PCB + SLIDE NUT.

*MOUNTING SCREW: 10-32 X 3/8" PHILLIPS PAN

PCB + SLIDE NUT.

1X1 EXTRUSION (LEVEL 1 PCB)-DESKTOP

2X1 EXTRUSION (LEVEL 2 PCB SANDWICH)

*M6 TAPPING TOOL REQUIRED FOR EXTRUSION PREPARATION.

*M6 SCREWS: M6X12mm FOR SHEET SIDES, M6X20mm FOR THICKER SIDES.

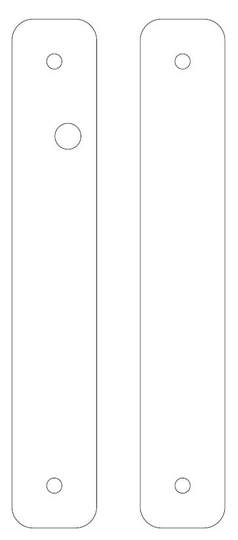

SIDE PANELS FOR 1X1 EXTRUSION. EXTF-7.5

Below is an example of a pair of side panels for EXTF-7.5. The pdf contains all the dimensions needed to drill your own holes.

One side gets a hole for the power barrel.

Below is an example of a pair of side panels for EXTF-7.5. The pdf contains all the dimensions needed to drill your own holes.

One side gets a hole for the power barrel.